There are several ways of finding out what Turbonetics turbocharger it is:

Easiest

- With a description on the box, invoice or shipping document

Easier

- With a Turbonetics part number (this is not a serial #)

- With a serial number (located on the anodized backplate)

Easy

- Measuring various components of the turbocharger; such as the compressor wheel/housing and turbine wheel/housing.

First and foremost, you should look at the turbocharger and see if it is indeed, a genuine Turbonetics turbocharger. You would be surprised to know how many ?Um?I THINK it?s a Turbonetics unit? calls we get.

All Turbonetics units feature:

- Polished compressor housing w/ Turbonetics logo engraved (Exept TN Series which have a non-polish compressor housing)

- Anodized gold, blue,silver or red backplate

- Various "T " stamping on cast parts

With a new purchase, you should be able to note the P/N and description listed on the shipment. Also, you can consult with your Turbonetics dealer you have purchased the unit from. Please note that Turbonetics turbochargers do not have a P/N listed on the unit. You may notice a 5-digit number tag on the backplate ? this is the serial number. Most serial numbers greater than T-20000 can be deciphered through the Turbonetics Owners Club and Turbonetics. If your unit is too old or does not come up in the database, you will have to measure various components to find out what it is.

Look for obvious things first, like the A/R on the turbine housing or whether the unit features a V-band connection or a flange discharge. A/R is usually listed right on the casting. It can be engraved on the outside or in the scroll. Having a V-band discharge on the turbine housing will tell you that it?s a T4 setup. All T3-style turbine housings will feature either the 4-bolt discharge, or the more popular 5-bolt discharge. But NO V-BAND!!! By looking at the size of the compressor housing, you will be able to find out what "family" of turbocharger it is (i.e. T-series, 60-series, T04E, T04B, etc). Use the following information to see where your unit fits in:

T-series/HP-series

4" inlet

2.5" outlet

60-series (smaller than T/HP-series)

4" inlet

2.5" outlet

TO4E

3" inlet (some in 2.75")

2.0" outlet

TO4B

2.75" inlet

2.00" outlet

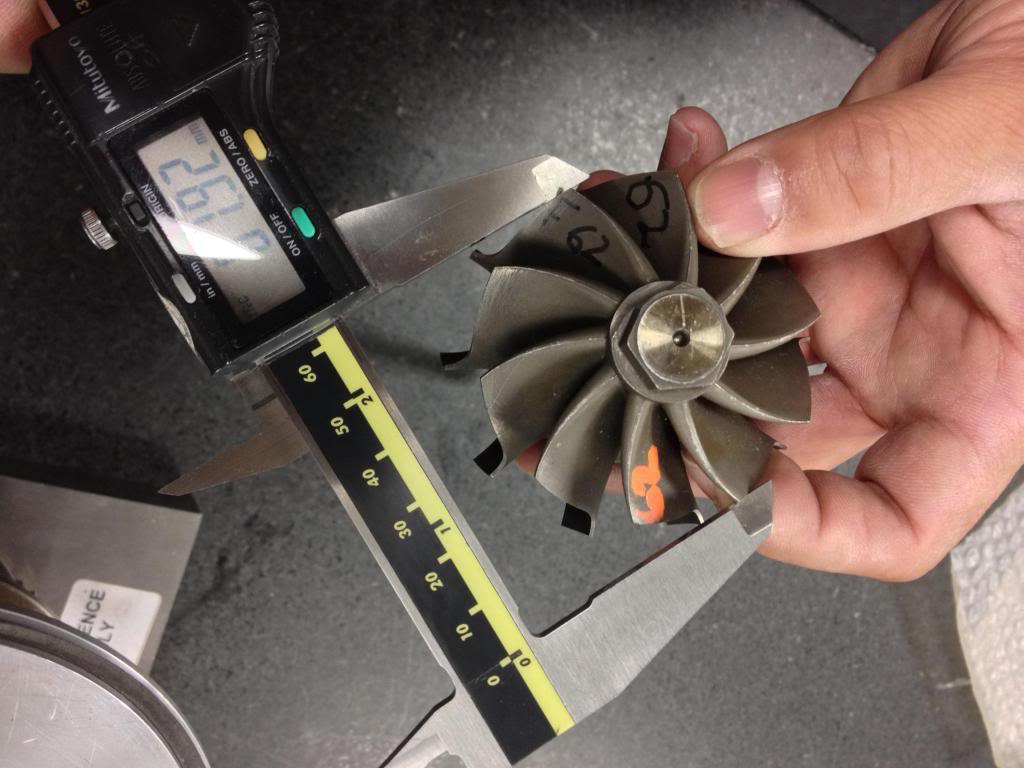

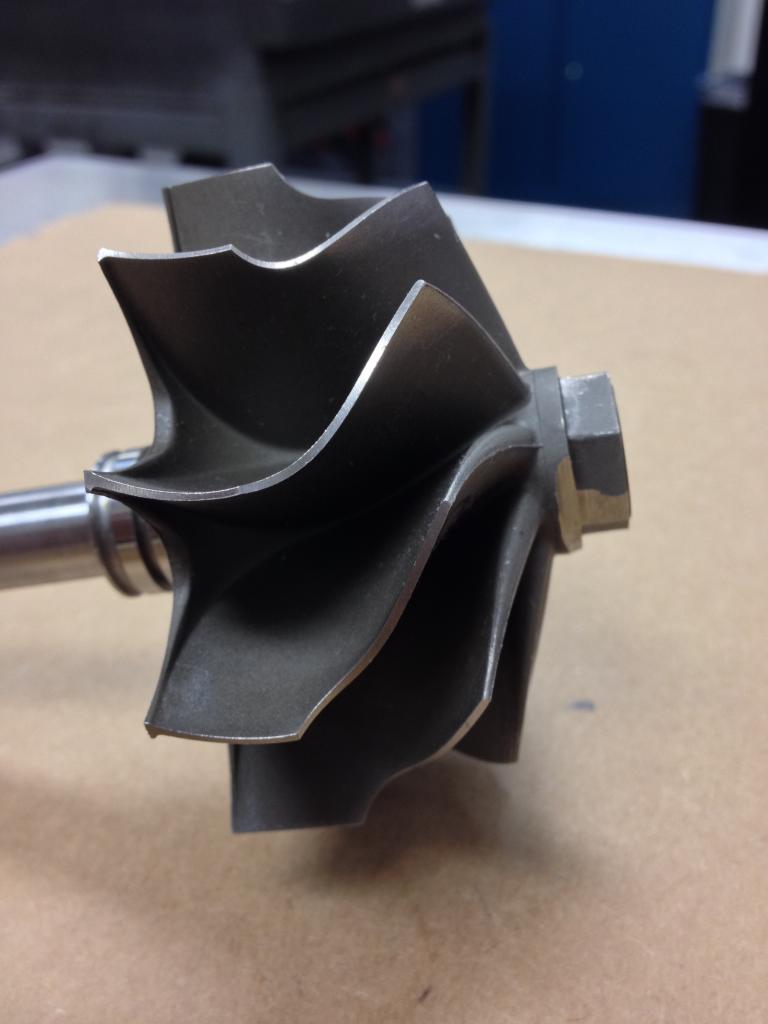

There are 2 diameters you have to measure on the compressor & turbine wheel minor and major. This task is to be completed with a precise measuring tool like a measuring caliper. No rulers or eye-balling! What am I measuring again? Please see below.

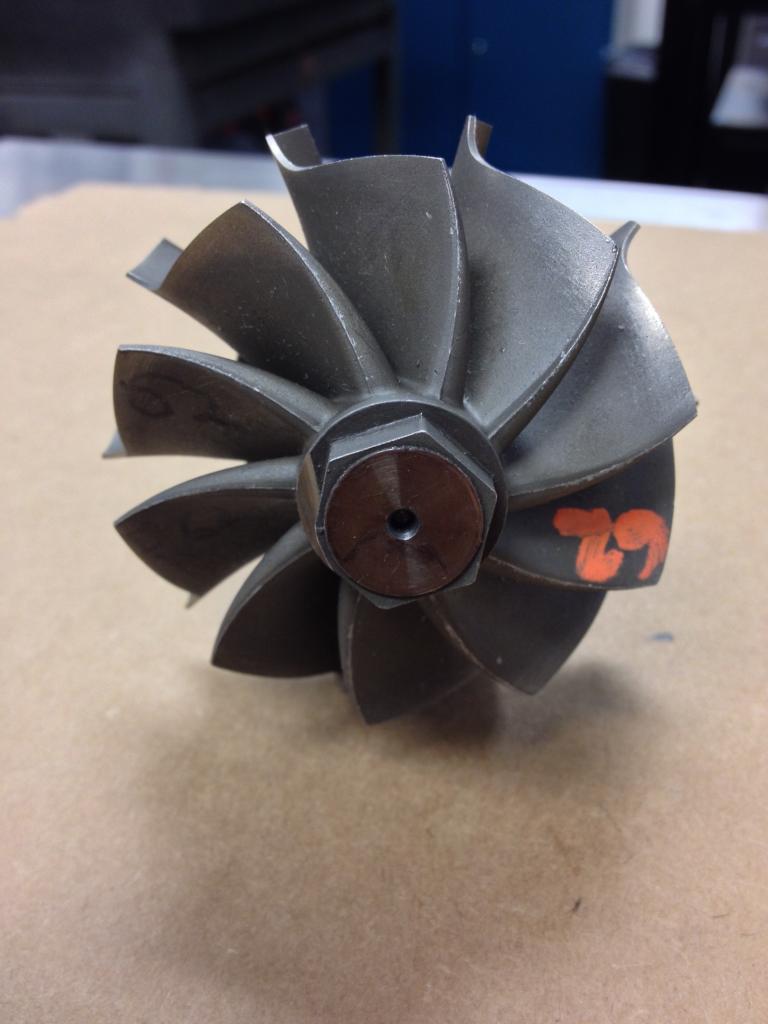

It's a little bit harder with a turbine wheel, but it's the same idea. After you get a successful measurement, grab yourself a nice beverage of your choice and look through wheel sizing on Turbonetics catalog.

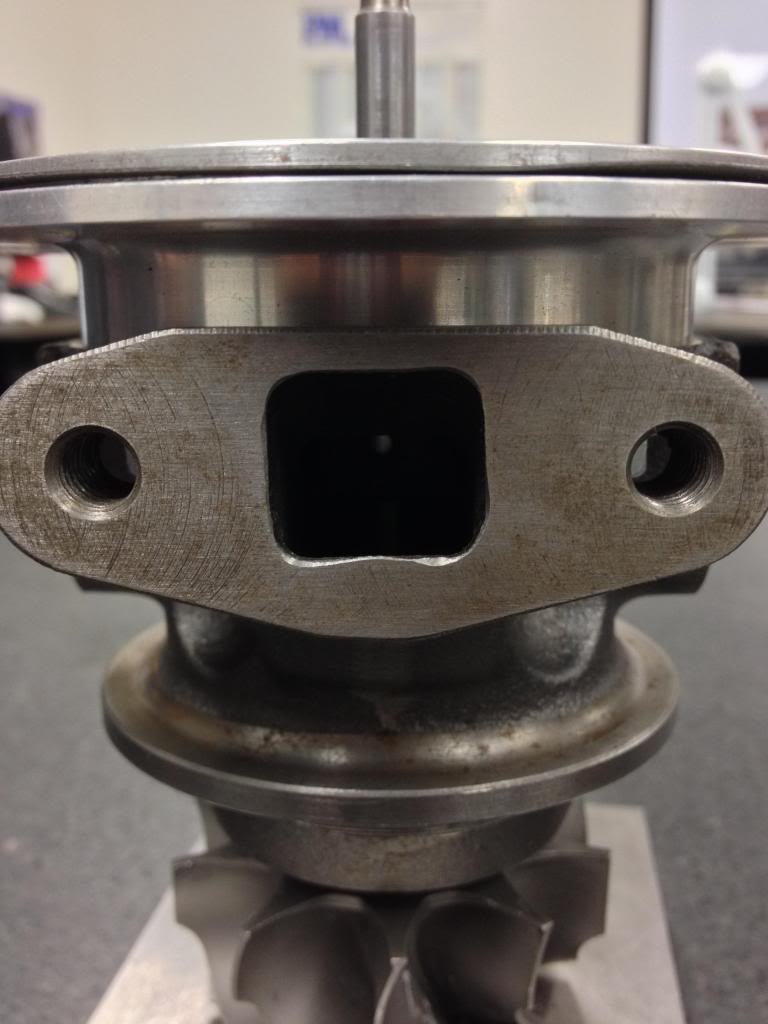

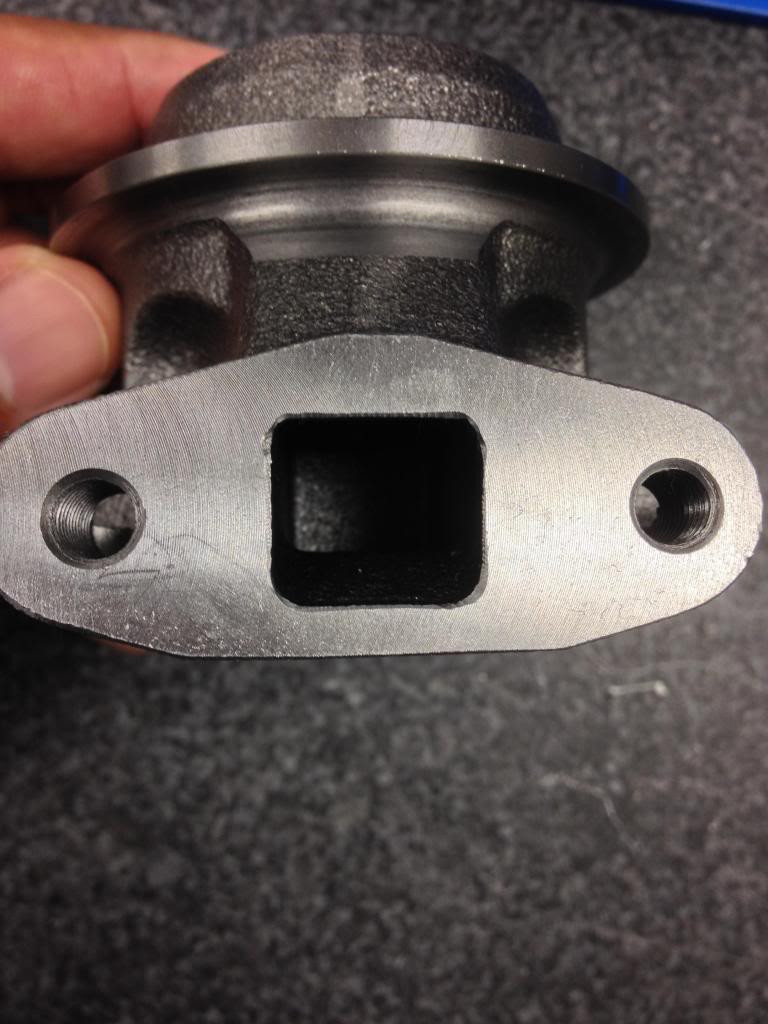

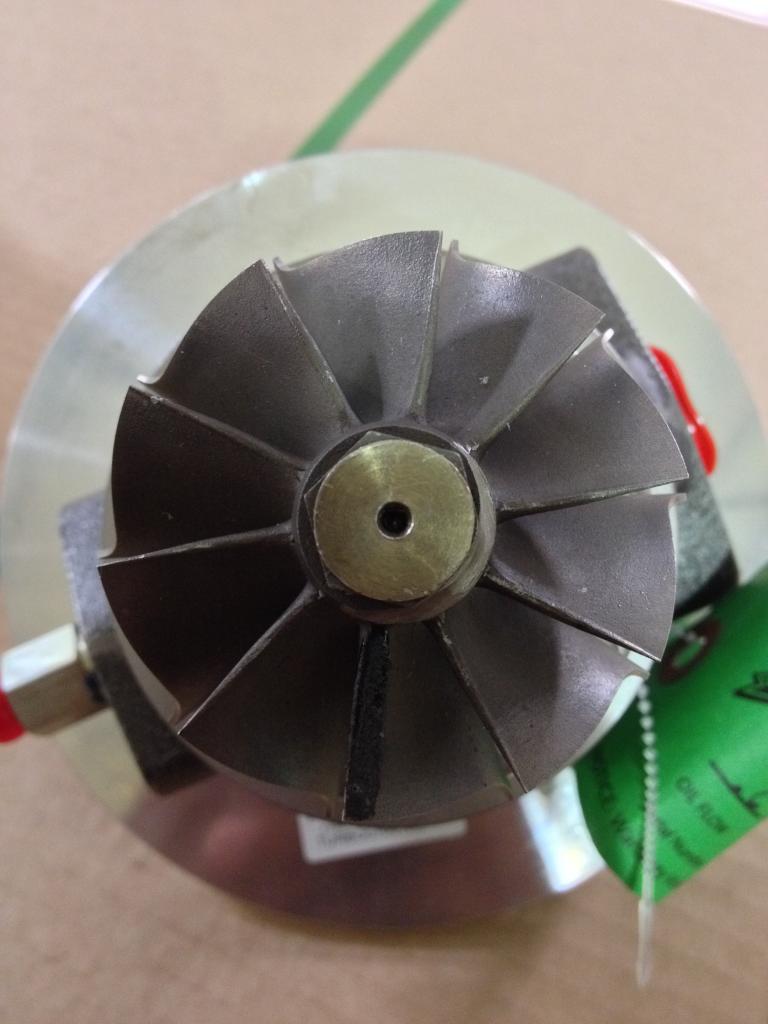

How do I know if this is a ball bearing unit?

I get asked this all the time. It?s a bit tedious but you can tell by looking up the oil drain hole. Removing the oil drain flange/gasket/fitting should make this easier. Assuming it's clean "up there", you should be able to see shiny ceramic outer race on the compressor side. No shine, no ball bearing.

Ball Bearing Example

Non Ball Bearing Example

Let me RESPECTFULLY say this first. Trying to identify your turbo after you have purchased it is like buying shoes that you dont know what size they are and hoping they fit when you get them. No matter how good of a deal they are if they dont fit it isnt a good deal.

Here is a quick reference guide with compressor and turbine wheel measurements:

T3 Compressor Wheels

Inducer dia. Major dia.

35 trim 1.396 2.367

40 trim 1.484 2.367

45 trim 1.595 2.367

50 trim 1.674 2.367

55 trim 1.760 2.367

60 trim 1.830 2.367

Super 60 trim 1.900 2.367

TO4B Compressor Wheels

Inducer dia. Major dia.

Super-S 1.904 3.00

Super-V 2.180 3.00

Super-H 2.300 3.00

TO4E Compressor Wheels

Inducer dia. Major dia.

40 trim 1.870 3.00

46 trim 2.003 3.00

50 trim 2.122 3.00

54 trim 2.168 3.00

57 trim 2.227 3.00

60 trim 2.285 3.00

TO4E Super Compressor Wheels

same as above except the major is 3.20

60 Series Compressor Wheels

Inducer dia. Major dia.

60-1 HI-FI 2.324 3.00

60-1 2.324 3.00

HP-61 2.418 3.228

62-1 2.441 3.00

T-Series Compressor Wheels

Inducer dia. Major dia.

HP-58 2.293 3.304

HP-61 2.418 3.228

HP-66 2.580 3.584

HP-70 2.733 4.030

HP-72 2.840 4.030

HP-76 2.941 4.030

HP-78 3.070 4.030

Turbine Wheels

Exducer dia Major dia

F1-49 1.929 2.320

F1-54 2.126 2.555

F1-57 2.244 2.555

F1-62 2.441 2.795

F1-65 2.559 2.920

F1-68 2.677 3.111

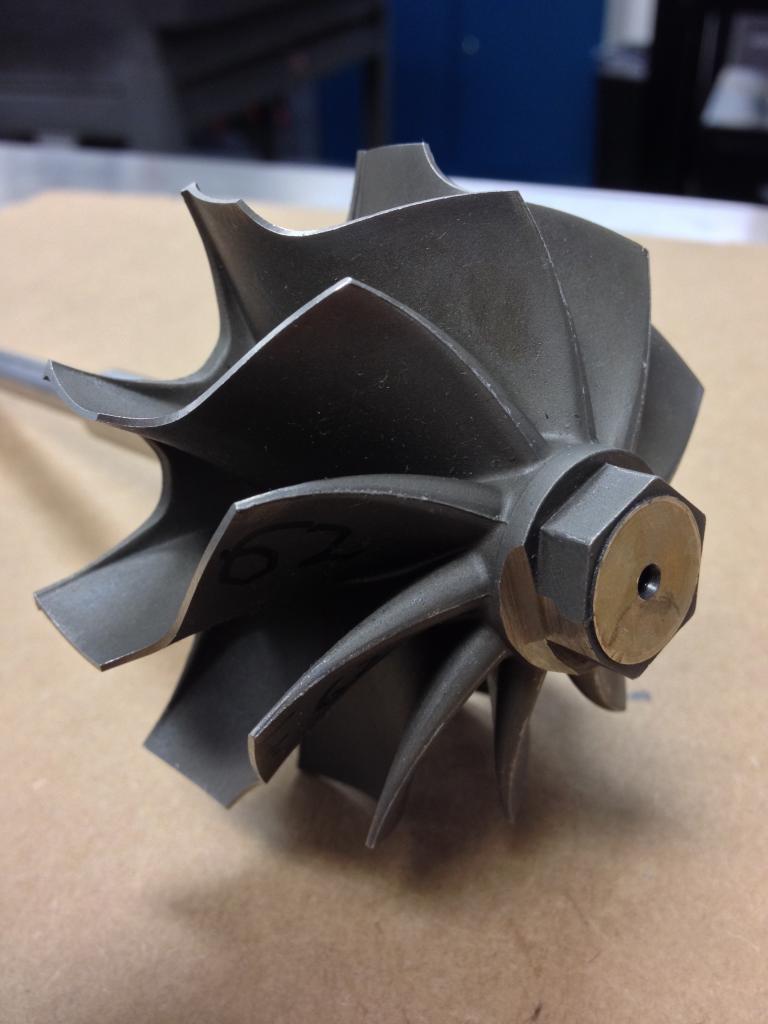

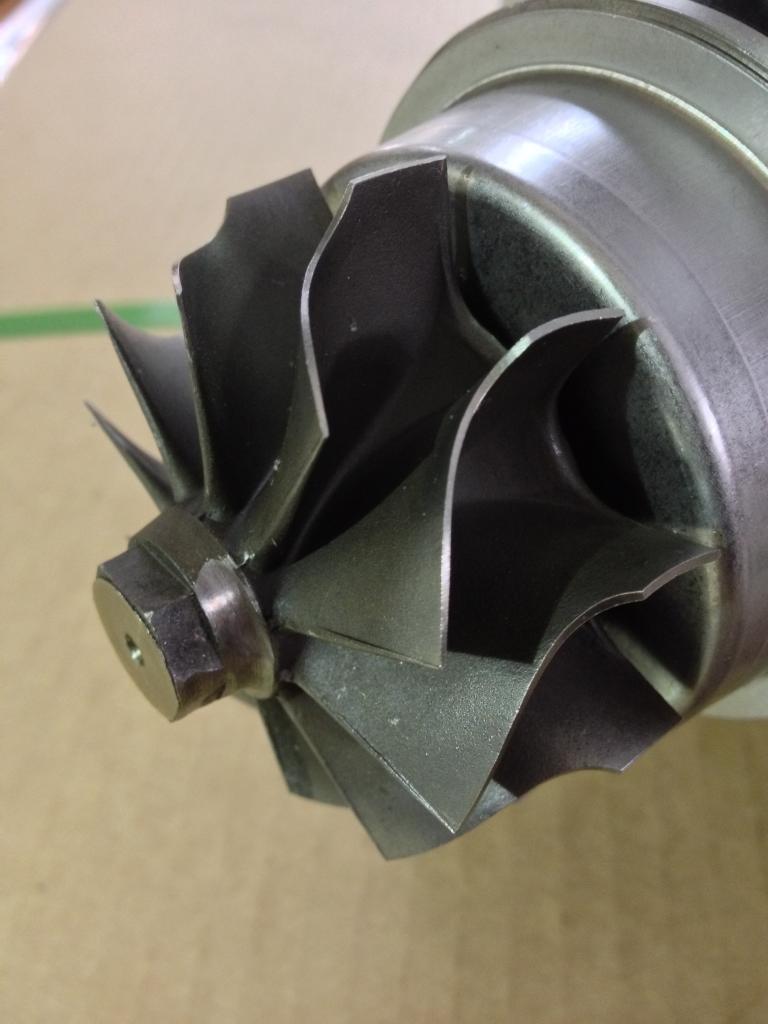

Another common question we get is how do I tell if I have the new F1 style turbine wheel. Please see the pictures below. The F1 turbine wheel has a taller tip height and is the wheel to the right in each picture.

Here are some samples of a Non-F1 (Stage) turbine wheel

Lastly when measuring you wheels please be sure to use a measuring caliper. You CANT get a accurate measurement by using a ruler or tape measure.

Turbonetics only re-builds and/or upgrades Turbonetics turbochargers

First contact the Turbonetics distributor that you purchased the product from. They will then contact our customer service department to receive an Inspection, Return, or Warranty number. ONLY products with the appropriate number will be accepted/serviced by Turbonetics.

It’s no longer necessary to use black magic or cast a voodoo spell to choose the right turbocharger. Turbonetics makes it easy! Each family of turbochargers features Turbonetics Top Performers based on the displacement and power. While there are many other variables to consider, these will certainly get you started. We have over 125 years of forced induction sales and engineering expertise in our building to help you select the best possible combination of turbochargers and intercoolers. Feel free to contact Turbonetics and or any of our distributors, if you have questions. The dealer locator feature is available online at the top right hand corner of the site.

HERE ARE SOME THINGS TO CONSIDER:

POWER:

• Think in horsepower not boost.

• Boost is just a number that you will have to run on your engine to make a certain horsepower.

• How much power do you want to make? Be realistic, the more accurate that you are, the better tuned your forced induction system will be.

• Can your vehicle (not just the engine, but the entire setup) handle such power?

• Remember the turbocharger is generally not the weakest link.

•Forged pistons, connecting rods, head studs, etc.

• “As much as possible” is not a goal.

INTENDED USAGE:

• What are you using the vehicle for?

• Race or street use?

• The way that you will be using the vehicle dramatically changes the sizing of the turbocharger and intercooler needs.

• Your choice of transmission type and gearing will greatly affect the performance and characteristics of the turbocharger, keep this in mind.

PACKAGING:

• Will the turbocharger(s) fit in your vehicles space constraints? Consider using differently sized compressor housings to more easily fit a given location.

REMEMBER TO CHOOSE WISELY:

Most street/autocross/drift enthusiasts will prefer a smaller turbocharger due to its fast response. A turbo system equipped with a smaller turbocharger is generally considered more fun to drive. The tradeoff is the final power output of the setup. On another note, dedicated track cars are aimed for peak power over boost response. There’s no doubt track cars spend more time in the upper RPM than average street cars. So, a small sacrifice in boost response is offset by the huge power potential. Larger frame turbochargers are preferred by track car owners due to their maximum power capacity. For most street applications the best solution for selecting turbine wheels and turbine housings, is to choose the smallest wheel diameter available that meets the horsepower level wanted.

It is also important to remember that response/spool-up time is greatly affected by turbine wheel diameter and turbine housing A/R. The A/R sizing can be used as a tool to fine tune the response range in the RPM band. The smaller the A/R, the faster the turbocharger will be able to spool up from the increase in exhaust gas velocity entering the turbine housing. Backpressure has become a major tuning issue associated with high performance turbocharged engines and the turbine wheel and turbine housing A/R are both critical to maximizing the performance of the turbo system. Backpressure is the pressure that the exhaust gas generates trying to enter into the turbine housing inlet. If backpressure becomes too great (a 2:1 ratio), the exhaust gases can not escape the cylinder head and can possibly cause major tuning, performance and durability issues. It is important to try to keep the backpressure to boost pressure ratio as low as possible and should be no greater than 1.5:1 for best performance (Example: 15 psi of boost to 22.5 psi of backpressure).

If you would like us to do a customized turbo match for you please fill out the form below and email it to info@turboneticsinc.com

You can find our basic drawings here.

No, all installs and or service must be performed by an Authorized Turbonetics Distributor or by the consumer.

The saying here is "if you can draw it, we can build it". Spearco offers complete custom intercooler applications. No matter if you are building a 800 cid big block monster or a 2.0L, we have the capabilities to match the perfect intercooler for your needs. Using Spearco's extensive intercooler core inventory and the talents of our fabricators, Spearco can find the unit that is perfect for your application.

Conventional intercooler cores are thin-walled, extruded aluminum tubes that are not designed to handle extreme boost pressures and limit cooling performance because of their narrow width. W.A.V.E. Technology Cores utilize the latest design advances in strength and durability and maximize cooling effectiveness through a greater surface area. Wider is better!

Turbonetics, Inc., home of Spearco Intercoolers, is proud to offer a new online intercooler section, which is completely revised and provides more application information than ever before. The Spearco section has been enlarged and includes a greater selection of dimensional drawings and other data with regard to air/air and air/liquid intercoolers in drag racing applications. In addition to the various cast-aluminum manifolds which are used on a variety of cores by cutting their length to match the core, Spearco can also fabricate special manifolds from aluminum sheet and channel for special applications to fit all intercooler installation requirements. Spearco can fabricate to customer specifications or sketches and also offers complete engineering assistance for intercooler design and application. In addition to the standard cores as listed herein, Spearco can manufacture special size bar and plate style cores in thicknesses of 1.25", 2.0", 2.25", 3.0", 3.5", 4.0", 4.5", and 6.0". Contact one of our sales representatives for any special size requirements. For custom fabrication, fax your specs on the Custom Intercooler Specification Fax Form.

Using any of the extensive line of air/air intercooler cores. Spearco can custom fabricate end tanks or intercooler manifolds in an endless number of configurations to fit individual specifications. Manifolds can be straight or tapered with tube sizes of 1.75", 2.0", 2.25", 2.50", 2.75", 3.0", and 4.0". In addition, the cast manifolds shown online can be modified by sawing off connections, capping, hole sawing, or welding in hose connections as required. Call today to custom build an intercooler that is right for you.

Air to Air Intercoolers:

Spearco offers basic air/liquid intercooler cores that can be combined in a large variety of ways to suit intercooler needs on Roots or Centrifugal superchargers and turbochargers. Refer to the detailed drawings. Air/liquid intercoolers operate by pumping cooled water through the cores either from a front-mounted radiator or heat exchanger, or chilled water produced by circulating the liquid through a container filled with ice, as used in drag racing. Depending on engine size and heat load, we recommend a container that will hold a minimum of 12 pounds of ice. If a front radiator is used, this should be as large as possible since the temperature of the liquid entering the intercooler determines the cooling effectiveness. We recommend a radiator as used on small automobiles with a minimum surface area of at least 260sq. inches. Radiator technology is preferable rather than oil cooler technology, as these are specifically designed to cool water/glycol. When these intercoolers are used with chilled water, it is possible in some cases, to get charge temperatures below ambient temperature. Therefore, remarkable increases in air density and power are possible.

Drag Racing With Air to Liquid Intercoolers:

There are diverse opinions about the advantage of air/liquid intercoolers versus air/air intercoolers in drag racing applications. Some say there is no advantage over air/air and they also say if there is an advantage it is offset by the added weight. The real facts are that other than a small additional weight factor, a proper application of an air/liquid intercooler will increase power more than enough to offset any additional weight, and will always yield superior performance over an air/air unit. Furthermore, the additional weight is sometimes needed for ballast, eliminating this disadvantage. To understand why air/liquid intercoolers are superior for drag racing, consider that the cooling medium in an air/air intercooler is the ambient temperature of the outside air at any given time. If we have an engine running at 30 psi of boost pressure, with an ambient temperature of 90ºF, depending on compressor efficiency, the discharge temperature will be approximately 400ºF. Assume that you have an air/air intercooler that can give 90% effectiveness at over 100mph and less at lower vehicle speeds. 90% at the above condition will give a temperature out of the intercooler of approximately 120ºF, and higher temperature out at lower speeds due to lower cooling and velocity across the surface of the core. Additionally, you are leaving the line with a hot intercooler caused by heating during burn out. Please donwload the Spearco Intercooler Spec sheet and Intercooler Drawing Template below to allow our sales team to best help select and configure the proper intercooler for you.

You have come to the right place. They are located here.